Effortless Guide to Fiber Optic Fast Connectors for Field Assembly

Understanding Fiber Optic Fast Connectors

The Basics of Fiber Optic Technology

Fiber optic technology has revolutionized communication by enabling the transmission of data at incredibly high speeds over long distances. Unlike traditional copper cables, fiber optics use glass or plastic fibers to carry signals using light. This innovation has significantly improved internet connectivity, telecommunication systems, and cable television networks.

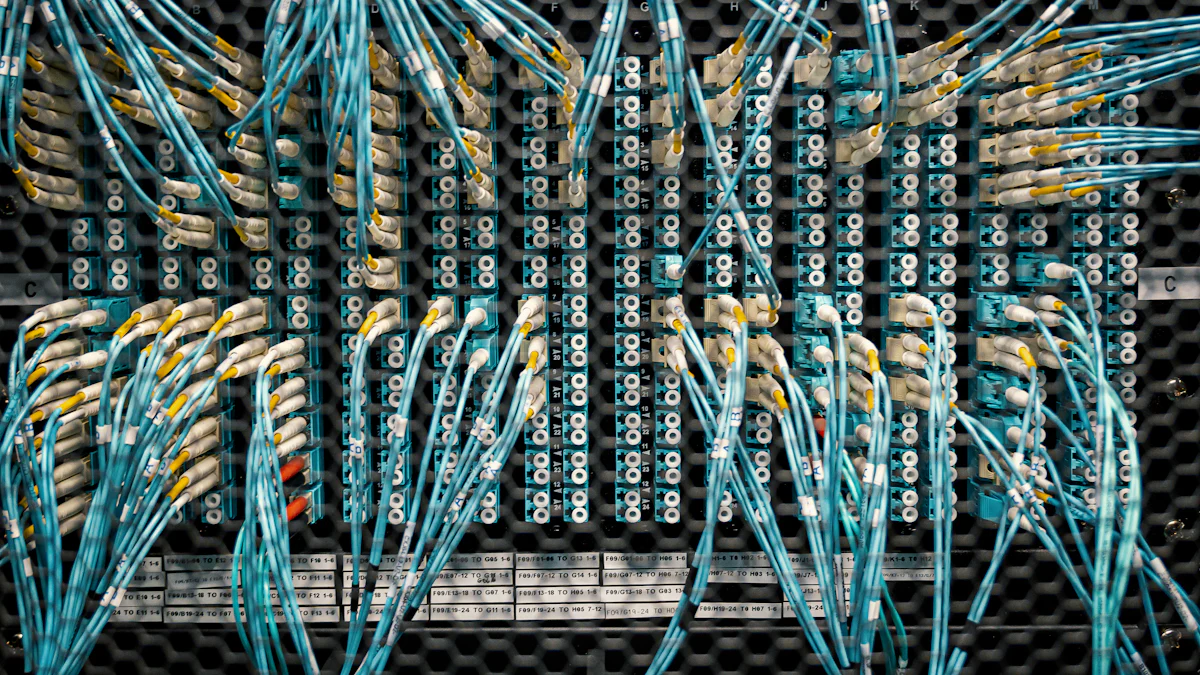

The Role of Connectors in Fiber Optics

Connectors play a crucial role in fiber optic technology by facilitating the seamless connection of optical fibers. These connectors act as the interface between individual fiber optic cables, ensuring efficient signal transmission without loss or interference. They are essential components that enable the creation of complex and reliable network infrastructures.

Why Fast Connectors?

Fast connectors are designed to streamline the field assembly process, offering unparalleled speed and efficiency when deploying fiber optic networks. Their rapid installation capabilities make them ideal for scenarios where time is of the essence, such as emergency repairs or rapid network expansion projects.

Speed and Efficiency in Field Assembly

Fast connectors excel in field assembly applications due to their ability to significantly reduce installation time. By eliminating the need for specialized equipment and intricate splicing procedures, these connectors enable technicians to swiftly establish connections in various environmental conditions.

The Importance of Dry St Technology

One notable feature of fast connectors is their utilization of Dry St technology, which eliminates the requirement for adhesives or curing processes during installation. This innovative approach not only accelerates deployment but also ensures a reliable and durable connection that withstands environmental challenges.

Exploring Types of Field Assembly Connectors

Field assembly connectors come in various types, each catering to specific deployment scenarios and environmental conditions. Understanding the distinct characteristics of straight-through type and pre-buried type connectors is essential for making informed decisions when establishing fiber optic networks.

Straight-Through Type Connectors

Design and Functionality

The straight-through type connectors are engineered to provide a direct, uninterrupted connection between two fiber optic cables. Their design features a simple yet robust mechanism that enables quick and reliable field installations. These connectors are equipped with precision alignment structures that ensure optimal signal transmission without compromising performance.

Ideal Use Cases

The versatility of straight-through type connectors makes them suitable for a wide range of applications. They are particularly beneficial in scenarios where rapid network deployment is required, such as temporary event setups, emergency connectivity restoration, or situations demanding immediate data transmission capabilities.

Pre-Buried Type Connectors

Understanding the Pre-Buried Advantage

Pre-buried type connectors offer a unique advantage by being specifically designed for underground deployment. Their construction includes protective elements that shield the connectors from environmental factors such as moisture, soil erosion, and physical damage. This ensures long-term reliability and stability in buried fiber optic networks.

When to Choose Pre-Buried Connectors

Selecting pre-buried type connectors is ideal for applications where durability and longevity are paramount considerations. These connectors are well-suited for permanent installations in outdoor environments, including underground cabling for telecommunications infrastructure, industrial monitoring systems, and subterranean data transmission networks.

Practical Applications and Benefits

Where Field Assembly Connectors Shine

Field assembly connectors demonstrate their exceptional utility in various applications, showcasing their adaptability and reliability.

Telecommunications and Broadband

The seamless deployment capabilities of fast connectors make them invaluable in the telecommunications industry. They facilitate the rapid expansion of broadband networks, enabling swift connectivity establishment in response to increasing bandwidth demands. Whether it's extending fiber optic lines to remote areas or quickly restoring communication links after natural disasters, fast connectors play a pivotal role in ensuring uninterrupted telecommunications services.

Industrial and Environmental Monitoring

In industrial and environmental monitoring systems, the efficiency of field assembly connectors is paramount. These connectors are instrumental in establishing robust data transmission networks for monitoring critical parameters such as temperature, pressure, and environmental conditions. Their rapid installation and durable connections contribute to the seamless operation of monitoring infrastructure, enhancing productivity and safety across various industrial sectors.

Advantages of Using Fast Connectors

Fast connectors offer a multitude of advantages that significantly impact deployment efficiency and network performance.

Reduced Installation Time and Cost

One of the primary benefits of fast connectors is their ability to drastically reduce installation time and associated costs. By eliminating complex splicing processes and specialized equipment requirements, these connectors expedite network deployment while minimizing labor expenses. This cost-effective approach makes them an ideal choice for projects with time-sensitive requirements or budget constraints.

Enhanced Performance and Reliability

Fast connectors are engineered to deliver superior performance and reliability in diverse operational environments. Their robust construction ensures consistent signal transmission quality, mitigating signal loss or disruptions commonly associated with traditional splicing methods. Additionally, their resilience against environmental factors contributes to sustained network stability, making them a dependable choice for long-term fiber optic installations.

Maintenance and Best Practices

Keeping Your Connectors in Top Shape

Maintaining the optimal performance of field assembly connectors is essential for ensuring reliable and uninterrupted data transmission. Two key practices contribute to keeping your connectors in top shape.

The Importance of Regular Cleaning

Regular cleaning is paramount to preserving the functionality of field assembly connectors. Dust, dirt, and other contaminants can accumulate on connector end faces, leading to signal loss and degraded performance. Implementing a routine cleaning schedule using specialized tools helps mitigate these issues, ensuring consistent signal quality and minimizing the risk of network disruptions.

Choosing the Right Cleaning Tools

Selecting the appropriate cleaning tools is crucial for effective maintenance. Fiber optic cleaning kits equipped with lint-free swabs, alcohol-based cleaning solutions, and inspection microscopes are essential for thorough connector end face cleaning. These tools enable meticulous inspection and precise cleaning, safeguarding the connectors against potential signal degradation due to contamination.

Installation Tips for Optimal Performance

When deploying field assembly connectors, adhering to best practices during installation significantly contributes to their long-term performance and reliability.

Avoiding Common Pitfalls

Avoiding common pitfalls such as excessive cable bending or improper connector handling is vital for preventing damage during installation. Mishandling can lead to misalignment or scratches on connector end faces, compromising signal integrity. By exercising care and precision during installation procedures, technicians can minimize the risk of performance issues arising from avoidable errors.

Best Practices for Field Assembly

Adhering to best practices throughout the field assembly process ensures optimal connector performance. This includes maintaining cleanliness in work environments, utilizing proper cable management techniques, and following manufacturer guidelines for installation procedures. By upholding these best practices, technicians can maximize the longevity and reliability of field assembly connectors in diverse operational settings.

In summary:

Regular cleaning with specialized tools preserves signal quality.

Choosing appropriate cleaning tools is crucial for effective maintenance.

Adhering to best practices during installation minimizes performance risks.

See Also

Comprehending Field-Installable Fiber Optic Connectors Without Epoxy

Becoming Proficient in FTTR with Nylon Cable for Fiber Optic Communication

Locating FastConnect Flat Drop Cable Assembly for FTTH with 1FO SM G657.A2

The Indispensable Handbook for 3M SC/APC Blue Fast Connector in Fiber Optics

Resolving Fiber Interconnection Hurdles with SC UPC Single-Mode Field Assembly Connectors