Understanding the Manufacturing and Specifications of GYFTC8Y53 Self-Supporting Figure 8 Cable

Dive into the World of Self-Supporting Figure 8 Cables

When we talk about Self-Supporting cables, we are delving into a unique category of cables designed to bear their weight and withstand environmental factors without the need for additional support structures. The Design Philosophy Behind Self-Supporting Cables revolves around engineering them to be robust and resilient in various conditions. This involves meticulous planning and construction to ensure that the cable can maintain its structural integrity over long distances.

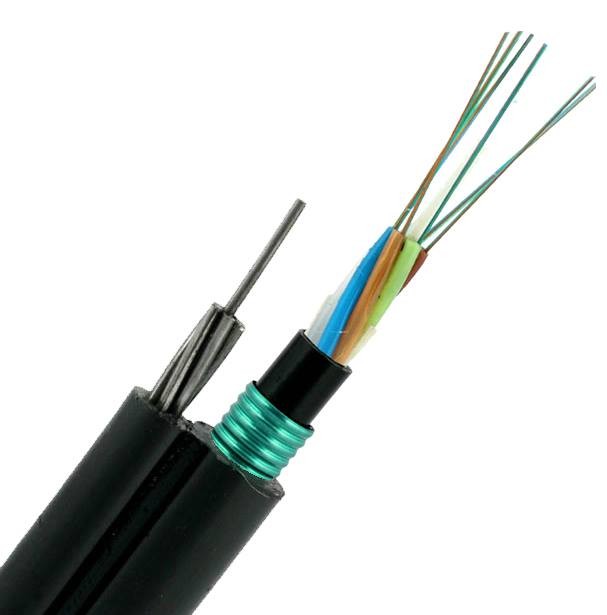

A Figure 8 Cable gets its name from its distinctive shape, resembling the number "8" when viewed in cross-section. This configuration plays a crucial role in making the cable self-supporting. By intertwining the fibers in this manner, it gains the ability to support its weight effectively. The unique structure also contributes to efficient installation, especially in aerial applications where it can be easily lashed to a messenger wire.

Now, let's explore why GYFTC8Y53 stands out among other options. Firstly, its Durability and Reliability Combined make it a top choice for telecommunications and networking projects. The sturdy design ensures that it can withstand harsh weather conditions and external interference, providing uninterrupted connectivity. Additionally, its Versatility Across Various Environments makes it suitable for diverse deployment scenarios, whether in urban settings or remote rural areas.

The Manufacturing Process of GYFTC8Y53 Cables

When it comes to the manufacturing process of GYFTC8Y53 cables, it's essential to understand the meticulous steps involved in transforming raw materials into a reliable and high-performance cable.

From Raw Materials to Cable

Selecting the Right Materials

The journey of creating GYFTC8Y53 cables begins with the careful selection of raw materials. High-quality optical fibers, typically made from glass or plastic, are chosen for their durability and signal transmission capabilities. The outer sheath material is also crucial, as it provides protection against environmental factors such as moisture, UV radiation, and temperature variations. By meticulously choosing these materials, the cable can withstand the demands of various deployment environments.

The Steps Involved in Cable Creation

Once the raw materials are selected, the manufacturing process kicks off with precision. The optical fibers are coated with protective layers and carefully arranged in a figure 8 configuration to ensure self-supporting capabilities. This intricate weaving process is followed by encasing the fibers within a robust outer sheath, providing additional protection and structural integrity. The cable is then subjected to stringent quality checks at every stage to maintain consistency and reliability.

Quality Assurance and Testing

Ensuring Every Meter Meets Standards

Quality assurance is paramount throughout the manufacturing process of GYFTC8Y53 cables. Each meter of cable undergoes thorough inspection to verify its mechanical strength, signal transmission efficiency, and environmental resilience. This meticulous approach ensures that every inch of cable meets industry standards for performance and longevity.

The Role of Rigorous Testing in Manufacturing

Rigorous testing forms the backbone of ensuring the reliability of GYFTC8Y53 cables. Various tests such as tensile strength evaluations, bending resistance assessments, and signal attenuation measurements are conducted to validate the cable's performance under real-world conditions. Additionally, environmental tests simulate extreme temperatures, humidity levels, and exposure to UV radiation to assess how well the cable withstands harsh surroundings.

Specifications Breakdown: Understanding 12 Core and 24 Core Variants

Now, let's delve into the specifics of the 12 Core and 24 Core variants of the GYFTC8Y53 cable. Each variant offers unique features and advantages tailored to different requirements.

Decoding the 12 Core Variant

Key Features and Ideal Use Cases

The 12 Core variant of the GYFTC8Y53 cable is designed with a focus on versatility and efficiency. Its compact design, housing 12 cores within a single cable, makes it an ideal choice for applications that require moderate data transmission capacity. This variant is well-suited for small to medium-scale networking projects, providing reliable connectivity without excessive bulk. Its key features include high signal integrity, efficient space utilization, and ease of installation.

The ideal use cases for the 12 Core variant span various scenarios such as residential broadband connections, small business networks, and localized telecommunications infrastructure. Its ability to efficiently transmit data over short to medium distances makes it a preferred choice for urban deployments where space optimization is crucial.

Why 12 Cores? A Look at Capacity and Efficiency

The decision to opt for 12 cores in this variant stems from a balance between capacity and efficiency. With an optimal number of cores, this variant can handle moderate data transmission requirements while maintaining cost-effectiveness. The 12 cores strike a harmonious equilibrium between performance capabilities and practicality, catering to a wide range of networking needs without unnecessary complexity.

Exploring the 24 Core Variant

Doubling Down on Performance

In contrast to its counterpart, the 24 Core variant takes performance to the next level by doubling the core count. This configuration significantly enhances data transmission capacity, making it suitable for larger-scale networking infrastructures. The increased core count allows for higher bandwidth capabilities, enabling seamless communication across extensive networks without compromising speed or reliability.

When to Opt for More Cores

The decision to opt for the 24 Core variant hinges on scalability and future-proofing network infrastructure. As data demands continue to grow in today's interconnected world, having additional cores provides room for expansion without requiring significant overhauls. It's particularly beneficial for enterprise-level deployments, long-distance telecommunications networks, and critical infrastructure where robustness and scalability are paramount.

Real-World Applications: How 116KM of Cable Powers Our Lives

When we consider the 116KM expanse of GYFTC8Y53 cable, its significance in modern telecommunications becomes evident. This extensive length of cable serves as the vital link connecting communities and facilitating seamless data transmission over vast distances.

The Significance of 116KM in Telecommunications

Connecting Communities: A Story of Distance and Data

The deployment of 116KM of GYFTC8Y53 cable is not merely about spanning geographical distances; it's about bridging communities. In rural areas where traditional connectivity infrastructure may be limited, this extensive length of cable plays a pivotal role in bringing high-speed internet and telecommunication services to remote regions. It fosters connectivity, enabling individuals, businesses, and institutions to access essential resources and communicate effectively regardless of their location.

The Backbone of Internet and Communication Networks

As an integral part of internet and communication networks, 116KM of GYFTC8Y53 cable forms the backbone that supports the digital infrastructure we rely on daily. It serves as the conduit for transmitting vast amounts of data, including voice calls, video conferencing, streaming services, and internet connectivity. Without this robust network foundation, the seamless flow of information across cities, states, and countries would be significantly hindered.

Beyond Telecommunications: Other Uses of GYFTC8Y53

Safety, Surveillance, and More

While telecommunications heavily relies on the capabilities of GYFTC8Y53 cables, their utility extends beyond traditional communication networks. In applications related to safety and surveillance systems, such as closed-circuit television (CCTV) installations and security monitoring, these cables play a crucial role in ensuring uninterrupted data transmission over long distances. Their reliability makes them indispensable for maintaining constant vigilance in various environments.

Innovative Uses in Various Industries

Beyond conventional applications, 116KM lengths find innovative uses across diverse industries. For instance, in the field of industrial automation where real-time data exchange is paramount for operational efficiency, these cables enable seamless connectivity between sensors, control systems, and central monitoring stations. Additionally, they are instrumental in supporting smart city initiatives by establishing interconnected networks for public services such as traffic management systems and environmental monitoring.

Wrapping Up

The Future of Fiber Optics

As we look ahead to the future of fiber optics, several trends and predictions in cable technology are shaping the landscape of connectivity. The demand for high-speed data transmission continues to surge, driving innovations in cable design and manufacturing processes. Additionally, advancements in material science and engineering are leading to the development of cables that offer enhanced durability, flexibility, and performance.

The emergence of Self-Supporting cables, including the renowned Figure 8 Cable, reflects a shift towards more robust and adaptable infrastructure solutions. These cables are designed to meet the evolving needs of telecommunications networks, providing reliable connectivity in diverse environments. As technology progresses, we can anticipate further refinements in self-supporting cable designs to accommodate higher bandwidth requirements and extended deployment scenarios.

How GYFTC8Y53 Fits into the Future Landscape

In this dynamic landscape of cable technology, GYFTC8Y53 is poised to play a pivotal role in meeting the escalating demands for efficient data transmission. Its innovative construction as a Self-Supporting Figure 8 Cable positions it as a versatile solution for various networking applications. With options available in both 12 Core and 24 Core variants, it offers scalability and adaptability to cater to a wide range of project requirements.

The durability and reliability combined with its self-supporting design make GYFTC8Y53 well-equipped to thrive in future telecommunications infrastructures. As data volumes continue to escalate, the capacity and efficiency offered by both the 12 Core and 24 Core variants will be instrumental in sustaining seamless connectivity across expanding networks.

Final Thoughts

As we conclude our exploration into the manufacturing and specifications of GYFTC8Y53 Self-Supporting Figure 8 Cable, it's essential to recap key points. We've delved into its unique self-supporting design philosophy, meticulous manufacturing process, specifications breakdown for both 12 Core and 24 Core variants, as well as real-world applications spanning telecommunications, safety, surveillance, and diverse industries.

This journey has provided insights into how cables like GYFTC8Y53 form the backbone of modern communication networks while adapting to future technological trends. Encouraging further exploration and learning about fiber optics will undoubtedly unveil new possibilities for connectivity solutions that shape our interconnected world.

See Also

Discovering 1FO SM G657.A2 FastConnect Flat Drop Cable Assembly for FTTH Usage

Becoming Proficient in Fiber Optic Communication: A Manual for Nylon Cable Usage in FTTR

Becoming Proficient in MPO/APC SM OS2 Singlemode OS2 Trunk Cable Technology

Comprehending Loose Tube, Gel-Free, All-Dielectric Cable with FastAccess Technology