Master Fiber Fusion Splicing: A Tapering Guide

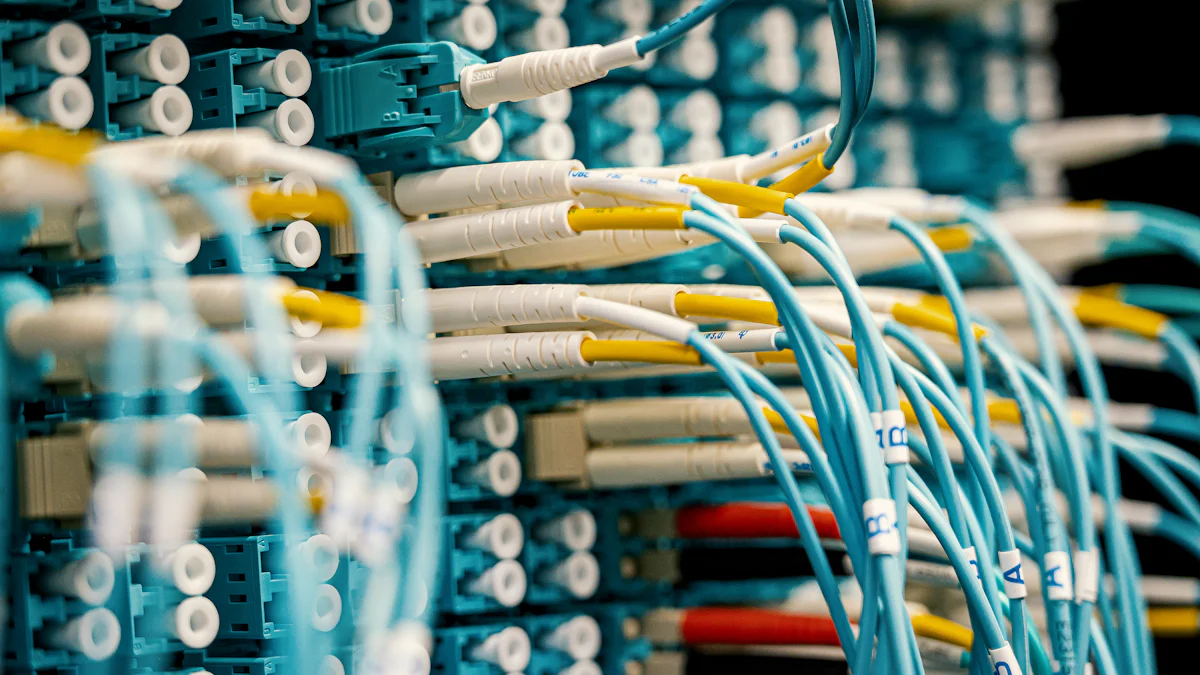

Fiber Fusion Splicing plays a crucial role in enhancing telecommunications networks. By seamlessly joining optical fibers, it ensures minimal loss and optimal performance. Introducing tapering as a technique to reduce splice loss further refines this process. This blog will delve into the significance of fiber fusion splicing, explore the art of tapering, and provide insights into achieving seamless connections in the realm of optical communications.

Understanding Fiber Fusion Splicing

In the realm of telecommunications, Fiber Fusion Splicing stands as a pivotal technique for creating seamless connections between optical fibers. This process is essential for ensuring minimal loss and optimal performance in data transmission. By exploring the basics and challenges associated with fiber fusion splicing, technicians can enhance their skills and contribute to the efficiency of modern networks.

Basics of Fiber Fusion Splicing

Definition and Importance

Fiber Fusion Splicing involves joining optical fibers to create a continuous connection that allows light signals to pass through without significant loss. This method is crucial for maintaining the integrity of data transmission in telecommunications networks.

The importance of Fiber Fusion Splicing lies in its ability to provide a reliable and low-loss connection between different fiber ends. This optimization ensures seamless communication within the network, facilitating faultless data transmission.

Common Applications

Fiber Fusion Splicing finds widespread applications in various industries, including telecommunications, healthcare, and aerospace. It is commonly used in creating long-distance communication links, network installations, and fiber optic repairs.

Challenges in Fiber Fusion Splicing

Splice Loss

One of the primary challenges faced in Fiber Fusion Splicing is splice loss, which refers to the reduction in signal strength at the splice point. Minimizing splice loss is crucial for maintaining signal integrity and ensuring efficient data transmission across optical networks.

Technicians must employ precise techniques during fusion splicing to minimize splice loss and optimize signal quality throughout the network.

Dissimilar Fibers

Another challenge arises when splicing dissimilar fibers that have different core sizes or materials. These variations can lead to increased splice loss and signal degradation if not addressed effectively.

Through proper tapering techniques before fusion splicing, technicians can reduce the diameter of dissimilar fibers gradually, ensuring a reliable joint with minimal insertion loss.

By mastering the fundamentals of Fiber Fusion Splicing and addressing its associated challenges, technicians can contribute significantly to enhancing network performance and reliability.

Tapering Techniques

What is Tapering?

Tapering in the realm of Fiber Fusion Splicing refers to the gradual reduction in diameter of optical fibers before splicing. This meticulous process plays a crucial role in minimizing splice loss and ensuring seamless connections between dissimilar fibers. By understanding the definition and purpose of tapering, technicians can enhance their skills and contribute to the efficiency of modern optical communication networks.

Definition and Purpose

Tapering involves reducing the diameter of optical fibers gradually to create a smooth transition between different fiber ends. This technique aims to minimize splice loss and optimize signal transmission efficiency by ensuring a seamless joint between dissimilar fibers.

The primary purpose of tapering is to achieve a reliable connection between optical fibers with varying core sizes or materials. By gradually reducing the fiber diameter, technicians can enhance core alignment precision and reduce insertion loss, leading to improved network performance.

Benefits of Tapering

Enhanced Signal Quality: Tapering facilitates optimal light signal transmission by reducing splice loss between dissimilar fibers, resulting in improved signal integrity across the network.

Minimal Insertion Loss: Through precise tapering techniques, technicians can achieve minimal insertion loss during fusion splicing, ensuring efficient data transmission without compromising signal strength.

Steps for Tapering

To master the art of tapering in Fiber Fusion Splicing, technicians must follow a series of meticulous steps to ensure optimal results and seamless connections between optical fibers.

Preparing the Fibers

Inspect Fiber Ends: Begin by inspecting the fiber ends for any imperfections or contaminants that could affect the splicing process.

Clean Fiber Ends: Thoroughly clean the fiber ends using specialized tools to remove any dirt or debris that may hinder proper fusion splicing.

Align Fibers: Precisely align the fibers using core alignment techniques to ensure accurate fusion during tapering.

Fusion Splicing Procedure

Set Splicing Parameters: Configure fusion splicer settings based on fiber type and diameter to achieve optimal fusion results.

Perform Fusion Splicing: Execute the fusion splicing process according to manufacturer guidelines, ensuring a strong bond between dissimilar fibers.

Monitor Fusion Process: Continuously monitor the fusion process to maintain control over temperature and alignment for successful taper creation.

Reducing Fiber Diameter

Apply Heat Gradually: Gradually apply heat to the fused region while applying opposing forces to reduce fiber diameter smoothly.

Control Taper Profile: Maintain control over taper profile by adjusting heat application and force distribution along the fiber length.

Verify Taper Quality: Inspect tapered region post-splicing to confirm uniform reduction in fiber diameter and minimal splice loss.

Achieving Optimal Results

In order to achieve optimal results when tapering dissimilar fibers before fusion splicing, technicians must focus on core alignment precision, ultra-low fusion splicing consumption, and protective coating removal techniques.

Core Alignment

Ensure precise core alignment between dissimilar fibers before tapering to guarantee minimal insertion loss and maximum signal transmission efficiency throughout the network.

Ultra-low Fusion Splicing

Implement ultra-low fusion splicing techniques during taper creation to minimize splice loss and maintain high signal quality across interconnected optical fibers.

Protective Coating Removal

Completely remove any protective coatings at the glass level before tapering dissimilar fibers through fusion splicing to facilitate proper fusion bonding and reduce signal attenuation within the network.

By mastering these tapering techniques, technicians can contribute significantly to enhancing network performance, reducing splice loss, and ensuring seamless connections in modern telecommunications infrastructure.

Best Practices and Tips

Ensuring Precision

Equipment Calibration

Proper equipment calibration is essential for achieving accurate fusion splicing results. Technicians should regularly calibrate fusion splicers to ensure precise alignment of optical fibers. By calibrating the equipment according to manufacturer specifications, technicians can optimize the splicing process and minimize insertion loss.

Steps for Equipment Calibration:

Follow Manufacturer Guidelines: Adhere to the calibration instructions provided by the equipment manufacturer to maintain accuracy.

Verify Alignment Accuracy: Use calibration tools to verify the alignment accuracy of the fusion splicer before initiating the splicing process.

Record Calibration Data: Keep a record of calibration data for future reference and quality control purposes.

Importance of Calibration: Proper equipment calibration enhances core alignment precision, reduces splice loss, and ensures consistent performance in fiber fusion splicing operations.

Environmental Control

Maintaining environmental control during fusion splicing procedures is crucial for minimizing external factors that could impact splice quality. Technicians should work in controlled environments with stable temperature and humidity levels to optimize fusion results.

Benefits of Environmental Control:

Temperature Stability: Stable temperatures prevent fluctuations that could affect fiber alignment and splice integrity.

Humidity Regulation: Controlled humidity levels reduce the risk of fiber contamination and enhance splice durability.

Best Practices:

Create a Controlled Workspace: Establish a dedicated workspace with proper ventilation and climate control systems.

Monitor Environmental Conditions: Regularly monitor temperature and humidity levels during fusion splicing tasks to maintain optimal working conditions.

Common Mistakes to Avoid

Misalignment

Misalignment during fusion splicing can lead to increased splice loss and signal degradation. Technicians must prioritize precise fiber alignment techniques to ensure seamless connections between optical fibers.

Preventing Misalignment:

Use Core Alignment Techniques: Employ core alignment methods such as active cladding alignment (ACA) or profile alignment system (PAS) for accurate fiber positioning.

Conduct Visual Inspections: Visually inspect fiber ends before splicing to identify any misalignments or irregularities that may impact splice quality.

Inadequate Cleaning

Inadequate cleaning of optical fibers before fusion splicing can result in poor splice quality and increased insertion loss. Technicians should adhere to proper cleaning procedures using lint-free wipes and approved solvents.

Cleaning Guidelines:

Remove Contaminants: Thoroughly clean fiber ends with lint-free wipes soaked in alcohol or specialized cleaning solutions.

Inspect Cleanliness: Verify cleanliness through visual inspection under magnification tools before proceeding with fusion splicing.

Future Developments

Advancements in Splicing Technology

Ongoing advancements in splicing technology are revolutionizing the field of optical communications. Innovations such as automated fusion splicers, enhanced cleaving techniques, and real-time monitoring systems are shaping the future of fiber fusion splicing.

"The integration of AI algorithms into fusion splicers enables automatic optimization of splice parameters, leading to faster and more efficient splicing processes."

Key Benefits:

Improved Efficiency: Advanced technologies streamline fusion splicing operations, reducing manual intervention and enhancing productivity.

Enhanced Quality Control: Real-time monitoring systems provide instant feedback on splice quality, enabling technicians to make immediate adjustments for optimal results.

Emerging Trends

Emerging trends in fiber optic splicing focus on sustainability, miniaturization, and enhanced connectivity solutions. Technologies like ribbon fiber splicing, biodegradable protective coatings, and multi-fiber connectors are gaining traction in the industry.

Industry Impact:

Sustainable Practices: Biodegradable materials promote eco-friendly solutions in fiber optic networks, aligning with global sustainability initiatives.

Compact Designs: Miniaturized components enable space-saving installations in dense network environments without compromising performance.

Connectivity Innovations: Multi-fiber connectors facilitate rapid deployment of high-capacity connections, catering to increasing bandwidth demands in modern networks.

By embracing these best practices, avoiding common mistakes, and staying informed about future developments in fiber optic splicing technology, technicians can elevate their skills and contribute effectively to advancing telecommunications infrastructure worldwide.

Methods for aligning fibers, the use of adhesives or welding, and the impact of multi-fiber splicing on cable design are crucial aspects in achieving low splice loss. The importance of fiber manufacturing tolerances cannot be overstated as it directly influences the quality of optical connections. Looking ahead, the focus will shift towards ensuring environmental stability of splices to guarantee long-term network reliability and performance. By mastering these techniques and embracing future advancements, technicians can elevate the standards of fiber fusion splicing in telecommunications infrastructure.

See Also

Expertise in Fiber Optic Communication: Nylon Cable Usage for FTTR

Comprehensive Insight into APC Simplex 9/125um 3.0MM ST Fiber Optic Pigtail

A Thorough Manual for 1x32 PLC Fiber Splitter with SC/APC Singlemode

Exploring MPO and APC 12 Core Fiber Optic Attenuators for Connectors

Insight into 2.0 x 5.0mm 1FO Mini SC FastConnect Field Connector